What is plastic coated paper?

- Category

- Subcategory

Plastic coated paper is a common material in everyday items like food packaging and disposable cups. It combines the strength of plastic with the sturdiness of paper. This makes it great for holding liquids and keeping products fresh.

But there’s more to it. As people grow more aware of environmental issues, we must understand plasticized paper and its impact on the planet. In this article, you’ll learn how it’s made, where it’s used, and what it means for the environment.

What is plastic-coated paper?

Imagine you have a regular piece of paper, like the one you might use for writing or printing. Let’s say you want to make this paper stronger and more resistant to water or oil, even if you want to give it a glossy look.

That’s where plastic-coated paper comes in. It’s like putting a protective layer of plastic over the paper. Manufacturers make this plastic layer with different plastics, such as polyethylene and polypropylene.

So, plastic-coated paper is a type of paper that has been covered with a thin layer of plastic. This plastic coating makes the paper more durable, water-resistant, and sometimes even shiny. It’s often used in food packaging, disposable cups, or labels. In these industries, the paper is tough and protected.

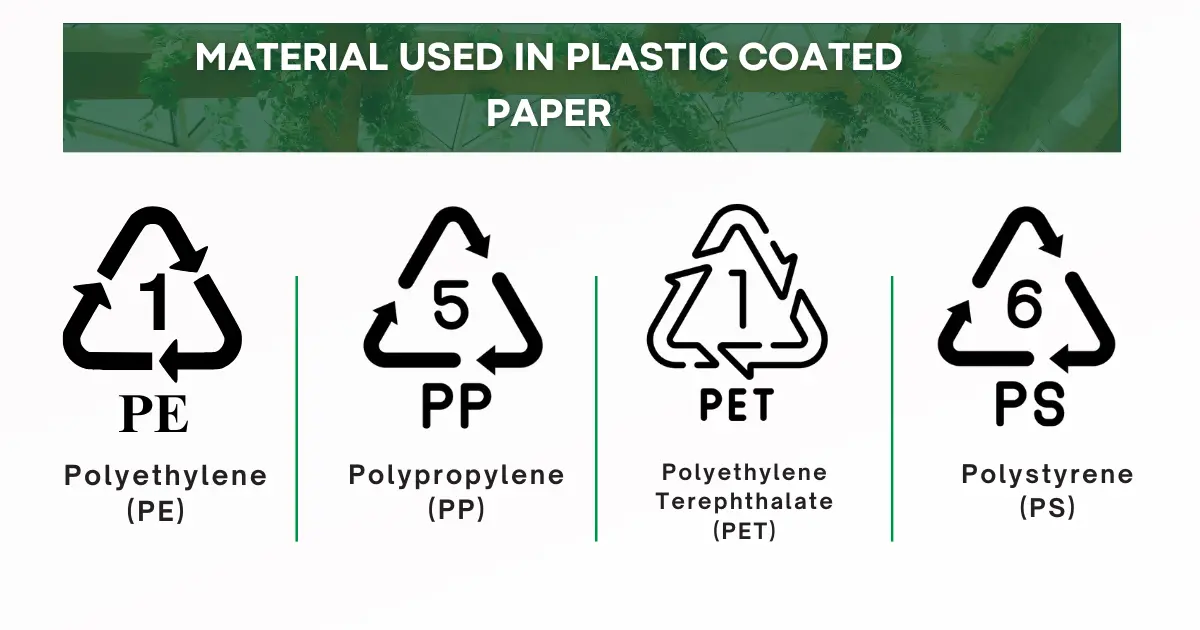

Which material is used for plastic-coated paper?

Plastic-coated paper is made by applying a layer of plastic onto paper. This gives it added protection and durability, as well as other functions. Various types of plastic are used for coating on paper. It depends on the desired characteristics and intended applications. Some common materials used to plastic coating on paper.

Polyethylene (PE): Polyethylene is one of the most common materials for coating paper. It offers excellent moisture resistance, durability, and flexibility. Paper coated with polyethylene is a common choice for food packaging. Most of the time for wrapping sandwiches, lining trays, or creating disposable cups.

Polypropylene (PP): Polypropylene is another type of thermoplastic polymer. It coats paper. It provides good clarity, strength, and resistance to grease and chemicals. PP-coated paper is often used in labels, pouches, and wrappers.

Polyethylene Terephthalate (PET): PET is a transparent, lightweight, and strong plastic material. It also has uses in the production of plastic-coated paper. It offers excellent barrier properties against moisture, gases, and aromas. It is suitable for applications like flexible packaging, labels, and laminates.

Polystyrene (PS): It is a clear, rigid, and versatile plastic. PS-coated paper is used in products like disposable plates, cups, and trays.

The choice of material for coating on paper depends on several factors. For the intended use, consider the barrier properties, printability, environmental impact, and regulations.

Manufacturing process of plastic coated paper

Base paper material: The process begins with wood pulp or recycled fibers.

Plastic coating applied: This base paper is then coated with a thin layer of plastic. Mainly uses polyethylene, polypropylene, or polyester for coating. The type of plastic used depends on the intended application and desired properties.

Purpose of the plastic coating: The plastic coating on paper serves several purposes. It protects the paper from moisture, enhances durability, and improves printability.

Characteristics of plastic-coated paper

Moisture resistance: The plastic coating keeps moisture from soaking the paper. It prevents sogginess and disintegration.

Durability and tear resistance: The plastic layer adds strength and tear resistance to the paper. It makes it more durable and less prone to tearing or ripping.

Printability: The smooth surface of the plastic coating provides an excellent printing surface. It allows for vibrant colors and crisp text or graphics.

Appearance and texture: Coated paper can have a glossy or matte finish in different types of coating. The paper with plastic coating also has a smooth or textured surface.

what is the use of Plastic-Coated Paper?

Food packaging

Paper coated with plastic dominates the food industry. We use plastic-coated paper for packaging products like candy wrappers, snack bags, and food containers. Its moisture resistance and durability make it ideal for protecting food items. It is also used for attractive packaging designs.

Industrial and commercial uses

Plastic-coated paper is also widely used in industrial and commercial settings. Durability and moisture resistance are important factors for envelopes, folders, and other office supplies. These industries use plasticized paper for that reason.

Plastic Coated Paper for Printing:

Plastic coated paper offers several advantages in printing, especially for materials requiring high-quality visuals and durability. Here’s why it’s widely used:

- The plastic coating protects against wear and tear, making it ideal for items like menus, brochures, or outdoor advertisements.

- The plastic layer repels moisture, ensuring the printed material remains intact even in humid conditions.

- The smooth surface allows for sharp and vibrant images, perfect for showcasing detailed designs and rich colors.

Using plastic coated paper for printing

Menus: Restaurants often use plastic coated paper for menus to withstand spills and frequent handling.

Signage: Outdoor signage benefits from the weather-resistant properties of plastic coating.

Catalogs and Brochures: High-end marketing materials use this paper type for its premium feel and durability.

Labels and Tags: Plastic coated paper is a popular choice for product labels and tags, ensuring longevity and an appealing finish.

Advantages of Plastic Coating on paper

Increased durability and longevity

The plastic coating significantly enhances the durability and longevity of the paper. It makes it resistant to various environmental factors and extends its usable life.

Moisture and grease resistance

After the paper coated with plastic the pimary advantages of its ability to resist moisture and grease. It is suitable where these factors are a concern, such as food packaging or outdoor signage.

Enhanced printability and vibrant colors

The smooth surface of the plastic coating allows for excellent printability. It results in vibrant colors, crisp text, and high-quality graphics.

Versatility in various applications

Plastic-coated paper’s versatility makes it suitable for a wide range of applications. The packaging, labeling, printing, and publishing industries use this plastic-coated paper.

Environmental Concerns

Is plastic coated paper recycleble?

While plastic-coated paper offers many benefits, it also presents challenges. The paper covered with plastic is difficult to recycle. Plastic coating makes it hard to separate the paper fibers during recycling. It leads to potential issues with contamination.

What is the Sustainable alternatives of plastic coated paper?

Every researcher and manufacturer is exploring sustainable alternatives for coating paper. Everyone wants to use bio-based coatings. They are made from plants or biodegradable polymers and are easy to recycle.

Efforts to reduce plastic waste

Also, efforts are underway to reduce plastic waste from plastic-coated paper products. This includes promoting proper disposal, encouraging reuse, and exploring alternatives to single-use packaging.

Future Trends and Developments

Innovations in plastic coating technologies.

As environmental concerns drive innovation, expect advances in plastic coating technologies. They will aim to improve sustainability and recyclability. They must also keep the desired properties of plastic-coated paper.

Eco-friendly and biodegradable alternatives

Developers are working on eco-friendly, biodegradable alternatives to plastic coatings. They may help reduce the environmental impact of plastic-coated paper products.

Potential new applications and markets

New research may create new uses for plastic-coated paper. This could expand its value in many industries.

Conclusion

Summary of key points

Plastic-coated paper is a versatile material. It has the benefits of paper and the durability and moisture resistance of plastic. This material is widely used in food packaging, printing, and publishing. Its unique properties and advantages make it valuable. Researchers explore innovative substitutes due to concerns about plastic waste.

Final thoughts on the importance and versatility of plastic-coated paper

As you’ve found, plastic-coated paper is vital in many industries. It balances function and looks. Its versatility makes it an important material today. It meets diverse needs. As you use various products and apps, take a moment to appreciate the ingenuity of this material. It helps meet our everyday needs.

FAQ

Plastic coated paper offers better moisture and heat resistance, while wax coated paper is less durable and more prone to melting.

Common plastics include polyethylene (PE), polypropylene (PP), and polylactic acid (PLA).

Plastic coated paper is generally not compostable or biodegradable unless it uses biodegradable plastics like PLA.

The plastic is melted and extruded onto the paper through a process called lamination or extrusion coating.